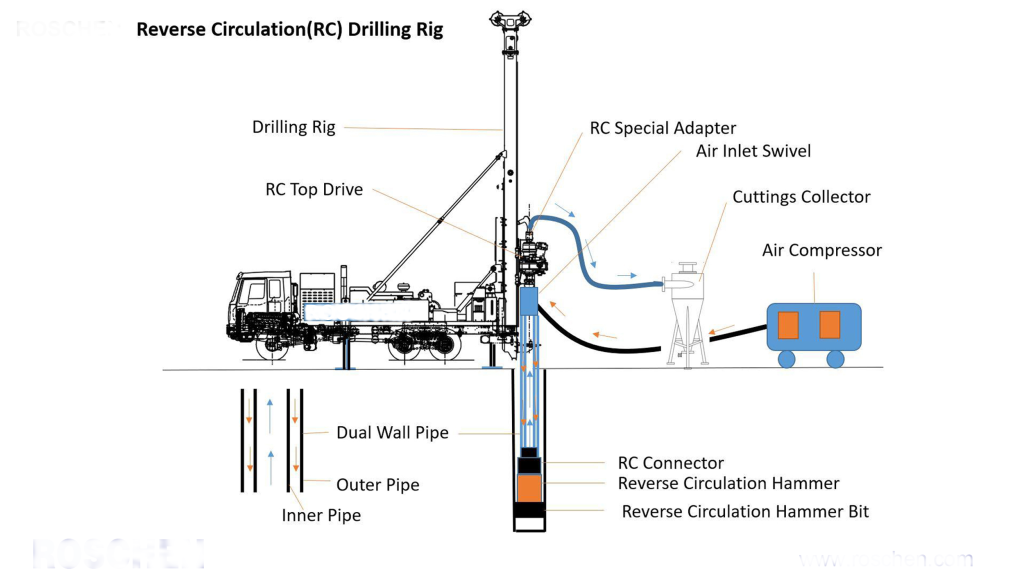

Reverse Circulation ( RC ) Drilling Rig Machine DC Drilling 300 Mm Hole Size

Dual-wall reverse-circulation drilling was developed in 1959 in Canada as a method to penetrate permafrost, glacial till, and other terrain where conventional drilling methods were costly and usually ineffective.

Dual-wall reverse circulation RC projects uses flush-threaded double-wall drill pipe and high-pressure air to provide continuous return of formation and water samples. Cuttings and formation waters are not contaminated with drilling additives or mixed with other borehole material. Up-hole velocity of about 70 ft/ sec provides reliable logging of water, mineral or contaminant-bearing strata. Water samples representative of specific strata may be airlifted or bailed to the surface.

In the percussion hammer system, dual-wall drill pipe is advanced through chiefly unconsolidated material by the percussion action of an above-ground pile hammer. The borehole is drilled and temporarily cased in one pass. Wells or monitoring devices are installed as the drill pipe is hydraulically retracted during construction. A rotary head may be adapted as an option to allow dual-wall rotary drilling into consolidated or crystalline formations through a percussion hammer drill string temporarily left in place as a conductor.

Contact us

💻 support@hydromontage.com